polyether polyol moisture meter|polyether vs polyester polyol : exporting This article highlights the differences between polyester polyols and polyether polyols in rigid foam polyurethane formulations to guide your selection for specific applications. WEB30 de set. de 2008 · Linwood Barclay. Linwood Barclay, critically acclaimed author of No Time for Goodbye, brings terror closer than ever before in a .

{plog:ftitle_list}

Família Sacana - O pézinho delicado . HQ72 - O pézinho delicado: Após dia cansativo, Dona Maria clama para Sr. Carlos fazer massagem no seu pé. Mesmo encontrando algo .

In order to ensure consistency, the water content of the raw polyols must be monitored to maintain uniformity between raw materials. Because loss on drying is not possible as most polyols will evaporate at high temperatures, the . This article highlights the differences between polyester polyols and polyether polyols in rigid foam polyurethane formulations to guide your selection for specific applications.When it comes to measuring the water content of a sample, the Karl Fischer method is widely regarded as the best option. A comprehensive approach involving volumetric and coulometric .

Bio-based Polyether Polyol Mn 1800-2200 Da; CAS Number: 345260-48-2; Synonyms: 1,3-Propanediol,Bio-based PPD,Homo polymer,PO3G,Polypropanediol; Linear Formula: .

polyether vs polyester polyol

Novel isocyanate-free moisture cure polyurethane coatings with excellent properties have been formu-lated and evaluated. These coatings utilize polyols derived from the renewable .The bio-based coatings prepared in this investigation provided useful physio-mechanical properties, chemical resistance, and water resistance compared to reference commercial . The moisture content of polyether polyols was measured by the Karl Fischer method using a CBS-1A model moisture content meter. Each sample was measured three .their linear structure,polyether polyols are used to synthesize PU as thermoplastics,elastomers,and fibers (10).The overall advantage of polyether polyols lies in their high hydrophobicity,low cost,low viscosity,and increased flexibility.These factors made polyether polyols the market leader,and their popularity is still growing annually.

Before installing the radar level meter, engineers first carried out the design and parameter setting of the system. They selected a radar level meter suitable for polyether polyols and set the appropriate operating frequency and measurement range according to parameters such as the dielectric constant and liquid density of polyether polyols.Polyether polyols were cheaper, easier to handle and more water-resistant than polyester polyols. . They may incorporate level sensors, conditioning jackets, and mixers. Pumps can be sized to meter in single grams per second up to . In particular, NX-9001 (formula PU 6) has replaced a sorbitol-based polyether polyol (PU 5), while NX-9008 and NX-9018 have been used as potential alternatives to a sucrose-based polyether polyol having a 360 mg KOH/g hydroxyl value.

Abstract A novel UV/moisture dual-curable polyurethane resin has been synthesized via a two-step process. In the first step, methoxysilane-modified polyether polyol (SPOL) was prepared through the thiolene click reaction between sulfhydryl group in (3-mercaptopropyl)trimethoxysilane (KH590) and vinyl groups in polyether polyol. In the second .Polyether polyols, which can be thought of as the backbone of many important polymers, are a group of polymers derived from simple alcohols and ethylene oxide or propylene oxide. They are the most widely utilized base in the production of polyurethanes, which are employed in a broad range of applications, including foam production, coatings . Recently, the preparation of PUFs with CO 2-based polyols has been attempted.An initial attempt to introduce PEC polyols into the formulation for flexible PU foams (FPUFs) was reported by Langanke et al. [].DeBolt et al. reported the preparation of FPUFs from blends of petroleum-based polyether polyols and CO 2-based PC polyols [].We also reported facile .

Protect from moisture/moist atmosphere (hygroscopic). Keep away from heat and all sources of ignition - No . SAFETY DATA SHEET POLYETHER POLYOL REVISION 4, DATE 16 JUL 2021 Form 21047, Revision 3, Page 5 of 10, 01-Oct-2024 02:27:04. Ecotoxicity Aquatic toxicity: Polyether Polyol Polyether Polyol < > Generally, polyether polyols with high functionality (3.0–8.0), low molecular weight (150–1000 g/mol), and high hydroxyl number (250–1000 mg KOH/g) are suitable for the production of rigid foams, . One-component systems consist of prepolymers with low isocyanate contents, which are cured by a reaction with moisture. Thus, .

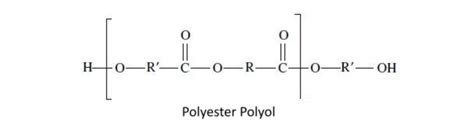

summary of the MDI, TDI, and polyether production process. Figure 2. Process summary for the production of polyurethane building blocks. TDI by BASF is an 80:20 mixture of the 2,4- and 2,6-TDI isomers assaying 99.5% TDI minimum, as shown in Figure 3. TDI is produced in several grades that differ slightly in acidity and hydrolyzable chloride .Polyether polyols have numerous uses. [16] [17] As an example, polyurethane foam is a big user of polyether polyols.[18]Polyester polyols can be used to produce rigid foam. [19] [20] They are available in both aromatic and aliphatic versions.[21] [22] They are also available in mixed aliphatic-aromatic versions often made from recycled raw materials, typically polyethylene . Traditional polyurethane reactive hot-melt (RHM) adhesives make use of blends of polyester, polyether and, in rare cases, conventional petroleum-based polycarbonate polyols. Although polyesters and polyethers contribute properties to RHM adhesives such as good workability and rapidly building strength, polyesters have poor hydrolytic stability and .

Polyether polyols are a type of polyol used extensively in the production of polyurethanes, found in products ranging from flexible and rigid foams to coatings, adhesives, and elastomers. Unlike polyester polyols, which are produced through esterification reactions, polyether polyols are synthesized through the polymerization of epoxides (also . A novel UV/moisture dual-curable polyurethane resin has been synthesized via a two-step process. In the first step, methoxysilane-modified polyether polyol (SPOL) was prepared through the thiolene .

Versatile polyether polyols give manufacturers more freedom. Which is why the Arcol® product line offers options for use across a wide array of products. This is possible because the range includes diol, triol and polymer polyols with .The polycarbonate polyols are characterized by superior heat and moisture resistance vs. polyester polyols. Performance with Corresponding Urethane Elastomers . Polyether and polyester polyols also exhibit a variety of .

Moisture contaminated isocyanates may appear cloudy, may contain solid material at the bottom of the container, or . This is also a best practice for polyols. When working with meter mix equi pment it is best to have a low-pressure source of nitrogen providing a continuous nitrogen head to materials. Alternatively, meter mix equipment can be .

Polyols are compounds possessing two or more hydroxyl functional groups that are available for organic reactions with isocyanates to produce PU [52].In other words, Polyol is responsible for providing long flexible segments, to build elastic polymers [53].There are different Polyols groups based on the type of monomer that makes them similar to polyester polyols, polyether . The hydroxyl group-terminated polyurethane prepolymers were synthesized using polyether polyols, monools, and hexamethylene di-isocyanate. Polyurethane PSA sheets were obtained by adding the tri-functional isocyanate to the hydroxyl group-terminated polyurethane prepolymers, coating on nylon non-woven fabric, and curing for five days at 50˚C.Polyether Polyol CARPOL® MX-425 is a Mannich-based polyether polyol. The resulting product has a nominal functionality of approximately four and a targeted hydroxyl number of 425. The presence of amine in this polyol creates a material that is autocatalytic. Due to this, CARPOL® MX-425 is suitable for spray foam formulations in addition to . 1 H-NMR spectra of polyether carbonate polyols before and after purification. Reaction condition: Catalyst amount = 50 mg, PO = 0.34 mol, PPG-600 = 0.25 mmol, toluene = 10 mL, PCO 2 = 30 bar, T P = 105 °C, t P = 3 h. As shown in Table 2, the DMC catalysts exhibited good to excellent activity for the PO/CO 2 copolymerization.

polyether polyols production as a category of major sources. The end use of a polyether polyol is determined by the properties of the polyol. Polyether polyols fall into two main classifications: high-molecular-weight, linear or slightly branched polyether polyols (urethanes), and low-molecular-weight, highly branched polyether polyols In comparison with the used polyether-type polyols, dimer fatty acid-based polyesters offer lower sensitivity to heat, oxygen and UV radiation, all of which attack ether bonds. The performance of dimer fatty acid-based polyurethanes was compared with an adipate polyester type and PTMEG diol in a Weather-O-meter experiment (see Figure 12).Polyether polyols are made by the reaction of organic oxide and glycol. Main organic oxide utilized are. China is currently the largest producer of polyether polyol ,with production capacity is about 6 million tons, accounting for about half of the global total . Designed to meet the demand for high-performance, moisture-resistant coatings .

polyether polyol vs polypolyol

Polyether provides much higher rebound and therefore is the choice for skate wheels and high-speed rollers. . Water and Moisture Resistance. If the product is to be submerged or used in a very humid condition it should be a. Polyether because . Polyether polyols of this type are prepared by ring opening polymerization of alkylene oxides such as ethylene oxide (EO), propylene oxide (PO), and butylene oxide (BO) in the presence of a starter molecule such as water, glycerin, or a higher functionality initiator. Basic catalysts like potassium hydroxide have long been, and continue to be .

does alkes test get harder

polyether polyol synthesis

WEBBahasa - Indonesia; Chinese (simplified) Deutsch; English - Australia; English - Canada; English - Ghana

polyether polyol moisture meter|polyether vs polyester polyol